Porsche PDK Transmission Problems

Common Issues Explained

Typical Symptoms, Common Problems, Concerns, Reliability, and Fault Codes with Porsche PDK Transmission

Typical Symptoms, Common Problems, Concerns, Reliability, and Fault Codes with Porsche PDK Transmission

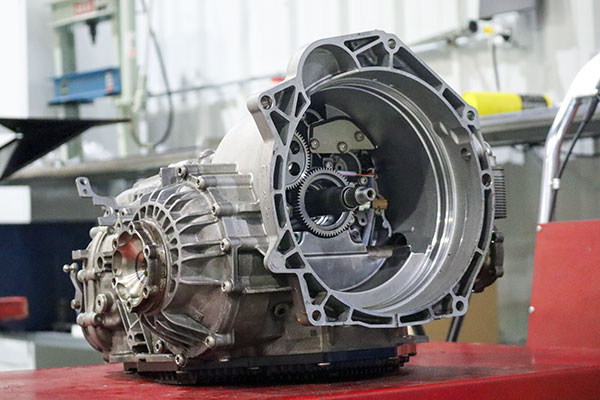

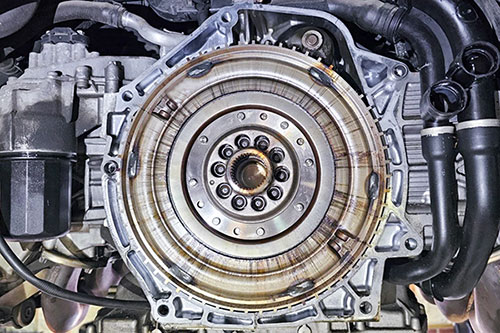

The Porsche-Doppelkupplungsgetriebe – which translates to Porsche double-clutch transmission or PDK is now the standard transmission fitted to most Porsche models.

In general, the Porsche PDK transmission is extremely reliable. However, a number of common issues have arisen with the PDK over time, and many have led to expensive repairs being deemed necessary.

The Porsche factory recommendations for maintenance for the PDK transmission have also evolved over time, with maintenance now being performed more frequently than originally recommended at the introduction of the transmission.

Major Concerns with the Porsche PDK Transmission

Major Concerns with the Porsche PDK Transmission

Interestingly, there aren’t many common mechanical failures with the PDK. The major problems with the PDK relate to the unwillingness of Porsche to allow the dealership channel to take the PDK apart and a lack of available parts!

The result tends to be recommendations to replace the PDK transmission, when in many circumstances, most of the reported failures tend to be associated with internal sensors. It’s probably best if you sit down – replacement of the PDK transmission is likely to be north of $18,000! For sure, inserting a new transmission will solve your PDK problems and get high scores for problem resolution. However, this seems to be an unfairly large spend put upon an owner, when repairs are available.

Don’t Replace Your Porsche PDK Transmission – It Can Easily and Economically Be Repaired

Don’t Replace Your Porsche PDK Transmission – It Can Easily and Economically Be Repaired

The good news is the Porsche PDK transmission is fully repairable for a fraction of the cost of replacement. And in more good news, repairs of the PDK transmission have led to expert knowledge enabling additional preventative maintenance that helps avoid the common issues that can arise with the PDK.

Recommended Porsche PDK Repair Specialist

We have partnered with MC Squared Autosport and highly recommend their Porsche PDK transmission repair service. Our PDK Repair specialist page highlights some of the common PDK repairs they provide, and preventative maintenance they recommend. Our advice is send your PDK transmission or your car to MC Squared Autosport for the most comprehensive PDK transmission repair service available.

Solving Porsche PDK Common Problems

How to Solve the Common Porsche PDK Problems

How to Solve the Common Porsche PDK Problems

Porsche PDK Replacement Parts

A limited number of parts, such as valve bodies and sensors are available from Porsche. Other parts are now available from third parties such as European Transmissions and T-design9 and JUMPS. Typically these parts are designed for the 7DT45 or 7DT70 PDK transmission used since 2009.

Porsche PDK Transmission – Problem Symptoms

Porsche PDK Transmission – Problem Symptoms

- Difficulty of lack of response when shifting gears.

- Unexpected gear changes while driving.

- Hesitation or jerking during gear shifts.

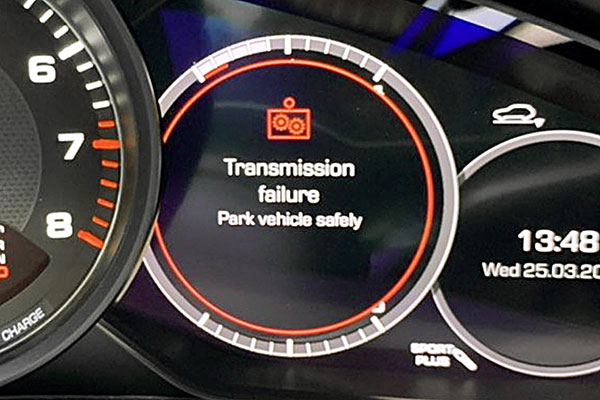

- Dashboard transmission warning light or message illuminates.

- Decreased vehicle performance.

- OBD fault codes recorded for the PDK.

- Fluid leaks.

Some of the likely dashboard warning messages can be seen in our section dashboard warning messages. In some cases the car will go into limp mode and no gear changes are possible. In other circumstances the car will not move at all.

Understanding Porsche PDK Transmission OBD Fault Codes

Porsche PDK Transmission Common Fault Codes

Porsche PDK Transmission Common Fault Codes

P1731, P1732, P1733, P1734, P1743, P17B1, P0711, P17F1

These fault codes typically point to electronic sensor problems within the PDK transmission. The common sensors to fail include:

- Distance sensor

- Speed sensor

- Pressure sensor

- Temperature sensor

Overview of Porsche PDK Transmission Sensor Fault Codes

- Fault code entries for distance sensor

P1731 … to P1734: Distance sensor information/shift rod faults - Fault code entries for speed sensor

P0730: Transmission monitoring symptom – incorrect gear ratio

P1743: Plausibility of transmission input shaft speed sensor clutch 1

P1744: Plausibility of transmission input shaft speed sensor clutch 2

P1745: Input shaft overspeed - Fault code entries for pressure sensor

P0841, P0846 and P0871: Pressure sensor fault (measured value implausible)

P17B1 and P17B2: Clutch fault (activation pressure implausible)

P17B3 and P17B4: Clutch valve fault (valve pressure stays too high)

P17BB … to P17BE: Clutch fault (clutch cannot be opened) - Fault code entries for temperature sensor

P0711: Transmission temperature sensor implausible

P172D: Transmission temperature sensor gradient fault

P17F0 … to P17F2: Transmission over temperature

Overview of PDK Transmission Software Fault Codes

Overview of PDK Transmission Software Fault Codes

- Fault Codes for Software Related Issues

P0602: PDK control unit not programmed

P0603 … to P605: PDK control unit, internal fault

P0614: Data status does not match engine

P0702: PDK control unit, internal fault

P1715: PDK control unit, internal fault

P1749: PDK control unit, variant coding invalid

P174B: PDK control unit, interchange detected

P174C: BIN file does not match software version

P174E: EEPROM content at system start incorrect/implausible

P18B4: PDK control unit, internal fault

P186F … to P1872: PDK control unit, internal fault (electric synchronization data, shift rod

compensation, clutches and hydraulics)

P1897, P189A, P189C, P189D: PDK control unit, internal fault (software monitoring)

P18A0 … to P18B5: PDK control unit, internal fault (software monitoring)

P18D0: Clutch, BIN file implausible

Overview of PDK Transmission Gear Selection Faults

- Fault Codes for Physical Gear Selection Issues

P17D0 … to 17D9: Hydraulic gear selection, system fault

P1779, P177A … to P177F: Synchronization fault – gear cannot be disengaged

P17E0 Hydraulic emergency hold function cannot be cancelled due to a mechanical blockage.

The fault can also be caused by a leak in the clutch pack if the expected pressure is not reached.

Porsche PDK Transmission Mechanical Problems

Porsche PDK Transmission Mechanical Problems

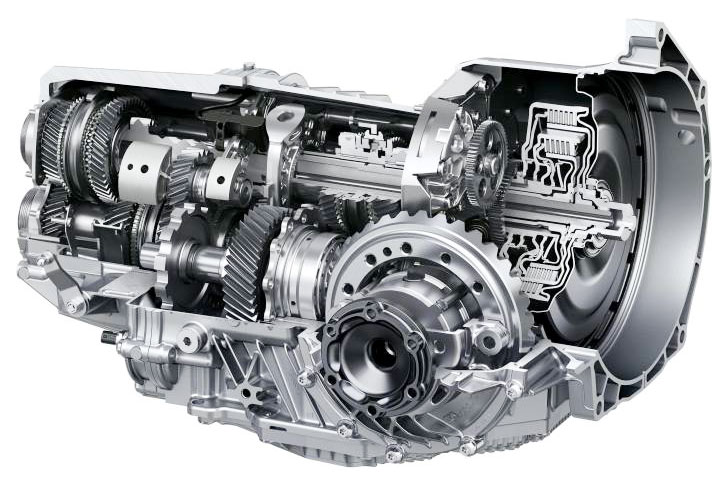

All transmissions experience mechanical issues during their expected lifecycle. The PDK transmission is no different, however, the PDK is often subject to more harsh conditions than a traditional automatic transmission, such as racetrack or HPDE.

Mechanical problems include fluid leaks, failures in the clutch pack, valve body failure, flywheel failure, and overheating. While, internally the build up of debris through poor maintenance can cause pressure and clutch pack issues.

Solving Porsche PDK Mechanical Problems

Unfortunately, the PDK is viewed in most of the Porsche dealer channel as a complete assembly replacement. We urge you to seek a second opinion if you have been told to replace your PDK and recommend MC² Autosport.

Solutions to Porsche PDK Mechanical Problems

Dashboard Warnings - Internal PDK Sensor Repairs

Transmission Dashboard Warnings

Transmission Dashboard Warnings

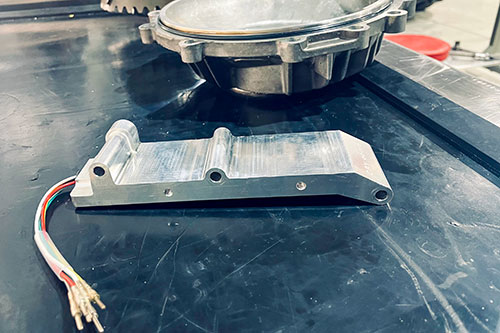

Internal PDK Sensor Repairs

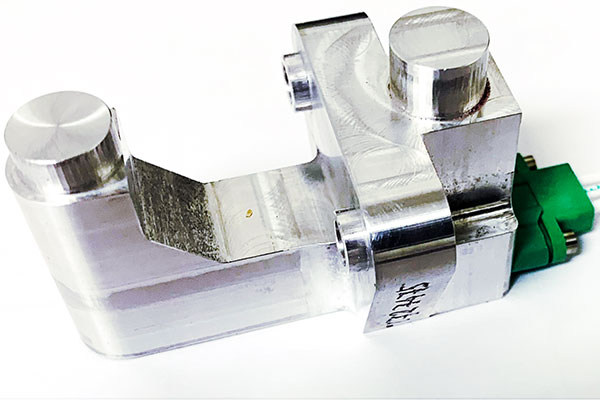

Failure of internal sensors within the PDK is commonplace. A series of dashboard messages and faults are reported through the OBD system. Often the car will have no reverse gear or go into a limp home mode. In some cases, the car will not move. Replacement of the sensors requires disassembly of the transmission, replacement of the sensors, and recalibration of the PDK in the car.

MC Squared Autosport uses the JUMPS speed and distance sensor set developed by Jeff Ricardson from Australia. The sensors come completely assembled with the correct pins and plug so no additional soldering work is required. The sensor set also includes improved internal logic vs. the original factory set. The logic update helps to guard against future failures and improves calibration after repairs.

The sensors are more likely to fail when maintenance is postponed to longer mileage durations. The sensor uses magnetic impulses to read information and is bathed in hot transmission fluid containing metal shavings from normal wear and tear. With a lack of fluid maintenance, they can easily become confused, covered in debris, and fail.

The sensors are more likely to fail when maintenance is postponed to longer mileage durations. The sensor uses magnetic impulses to read information and is bathed in hot transmission fluid containing metal shavings from normal wear and tear. With a lack of fluid maintenance, they can easily become confused, covered in debris, and fail.

Based on the common failures that MC² sees, they recommend you change the PDK transmission fluid every 30K miles. This helps to improve the longevity of the sensors and the clutch packs.

In the event of a PDK sensor failure, it makes sense to take a additional steps, such as the clutch cover locks, to prevent the need for additional costly repairs in the future.

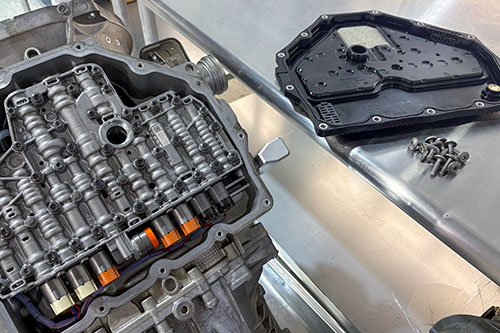

Rough Gear Shifts – PDK Valve Body Repairs

Rough Gear Shifts, Strange Noises

Rough Gear Shifts, Strange Noises

PDK Valve Body Repairs

Your Porsche PDK should smoothly and rapidly change gears. A drop in performance or poor gear shifting is commonly a sign of valve body issues. The valve body is responsible for the physical change of gears and the directing of transmission fluid to enable that process. Valve bodies can fail or become less efficient at changing gears for several reasons.

Replacing the valve body does not require the removal of the transmission and typically resolves the gear shift issue provided no other symptoms are evident – such as fluid intermix – see below.

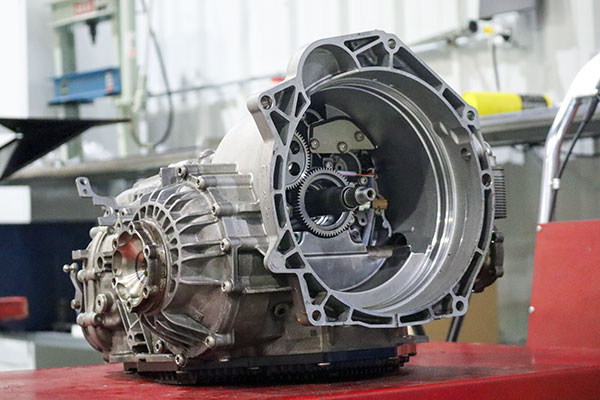

Slipping Gears – PDK Clutch Pack Repairs

Slipping Gears, Loss of Power

Slipping Gears, Loss of Power

PDK Clutch Pack Repairs

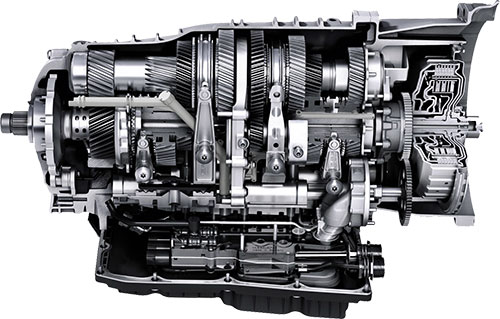

Failure in the PDK clutch pack results in loss of power, poor gear changes, and eventually a slipping transmission. Replacement or an upgrade to the clutch pack solves this problem. Replacement of the clutch pack does require the removal of the transmission from the car.

Why Did the Clutch Pack Fail?

Understanding how and why the clutch pack failed may save a good amount of money going forward. The clutch pack can be worn quickly with HPDE or racetrack driving. If this is the cause of the clutch pack failure MC Squared Autosport can upgrade your clutch pack to prevent this from happening again with a Dodson race clutch that supports up to 1000+ HP.

Leaking PDK Fluid

A common sign of clutch pack failure is PDK fluid leaking from the bell housing or vent. Historically, this has been a cause for complete PDK transmission replacement at the dealer. It’s important to note that while the clutch material may look to be in ok condition, if a leak is evident, the pack itself, and the rotating assembly, will have been compromised. Ultimately this is caused by a flywheel failure.

MC² Anti-Rotation Locks for PDK Clutch Pack Cover

MC² Anti-Rotation Locks for PDK Clutch Pack Cover

MC Squared Autosport has developed anti-rotation locks for the clutch pack cover. When the flywheel fails, the clutch cover slips, then rotates in place causing the dreaded bellhousing leak. With the MC² locks in place, you can prevent the slip and rotate with the clutch cover and allow for service of the flywheel alone. This saves a considerable amount of money on future repairs.

Fluid Intermix Causes PDK Clutch Pack Failure

Failure of a PDK clutch pack, or valve body on a street car is often caused by the intermixing of the two different fluids in the PDK transmission. The intermix of the fluid causes the clutch pack to fail, valve body issues, and sensor problems. The most common reason for this type of failure is outside influences, such as:

1. Filling the PDK fluid side with gear oil or filling the gear oil side with transmission fluid.

2. Breaking the internal axle shaft seal when repairing or replacing an axle.

PDK Leaking Front Cover – PDK Flywheel Repairs

PDK Leaking Front Cover

PDK Leaking Front Cover

PDK Flywheel Repairs

A common sign of clutch pack failure is PDK fluid leaking from the bell housing and or vent.

Historically, this has been a cause for complete PDK transmission replacement at a dealer. It’s important to note that while the clutch material may look to be in ok condition, if a leak is evident, the pack itself, and the rotating assembly, will have been compromised and will need to be replaced.

Ultimately this leak is caused by a flywheel failure. When the flywheel fails, the clutch cover slips, then rotates in place causing the dreaded bellhousing leak.

Signs of a Failing PDK Flywheel

Signs your PDK flywheel needs to be replaced are subtle. An extra bump when you shift from park to drive for example, or a small shudder when in drive and moving from a stop to the gas pedal. It’s subtle enough and changes over time that with street driving, many people do not notice until it’s too late.

Mileage is not a good means to measure flywheel maintenance, rather, the way the car is driven is a better indicator of potential issues. Flywheel maintenance on the PDK is not dissimilar to that of manual cars. The flywheel is a longer-term maintenance item. Recognizing the potential issues and addressing the replacement before damage occurs, can save you headaches and much more expense later.

Preventing Damage from PDK Flywheel Failure

Preventing Damage from PDK Flywheel Failure

MC Squared has developed a unique set of locks that prevent the clutch cover from rotating in place if a PDK flywheel fails. This is a preventative maintenance recommendation that should be added to any PDK repair. The lock set is designed to localize the failure to the flywheel and prevent damage to the PDK transmission.

MC² Anti-Rotation Locks for The PDK Clutch Pack Cover Saves Future Repair Cost

With the MC² locks in place, you can prevent the slip and rotate of the PDK clutch cover and allow for service of the flywheel alone. This saves a considerable amount of money on future repairs. MC Squared provides a unique PDK flywheel replacement service to prevent the exchange of the transmission being necessary.

Fluid Intermix – Gear Oil and PDK Transmission Fluid Mixed

Gear Oil and PDK Transmission Fluid Mixed

Gear Oil and PDK Transmission Fluid Mixed

The intermix of the two fluids in the PDK causes the clutch pack to fail, valve body issues, and sensor problems. The most common reasons for this failure are caused by outside influences. The most prevalent are:

1. During maintenance, filling the PDK fluid side with gear oil or filling the gear oil side with transmission fluid.

2. Breaking the axle shaft seal when repairing or replacing an axle.

PDK Internal Bearing Failure

PDK Internal Bearing Failure

The main internal bearings of the transmission are robust, but just like any sealed bearing there is a certain lifespan. The bearings hold the internal gear stacks in place in their respective housings and there are 2 matching sets for a total of 4 bearings. Until recently these have been unavailable, but now MC² can completely remove and replace them with new units and prolong the life of the PDK transmission even further.

Recommended Porsche PDK Transmission Maintenance

The original Porsche recommended maintenance cycle on the PDK transmission when it was first introduced was 120K miles or 12 years! This has proved to be problematic to say the least. Current recommendations for the 911 992 for example, half that time and mileage to a recommended 60K miles or 6 years.

Maintenance will almost never solve a transmission issue. However, it can certainly prevent some of the debris, leaks, sensor, or blockage issues that have arisen with the PDK transmission. We recommend you don’t let your PDK maintenance slip. If you have purchased a used car and have doubts about the last PDK service date, go ahead and get the maintenance done anyway.